Recent Projects by Wingra Engineering

Wingra Evaluates Power Plant

Compliance with New SO2 Air Quality Standard

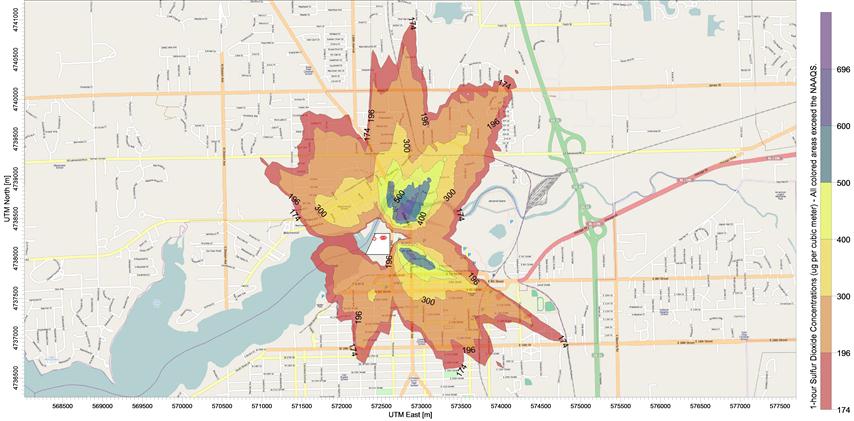

On

June 2, 2010, EPA lowered the National Ambient Air Quality

Standard (NAAQS) for sulfur dioxide (SO2).

The new standard is expected to improve public health protection,

especially for children, the elderly, and people with

asthma. In 2011, Wingra Engineering evaluated

over fifty U.S. power plants to help USEPA, state and

local air agencies identify facilities not complying with the new

air quality standard. The power plants were located in numerous

states including Maine, New Hampshire, Massachusetts,

Pennsylvania, New York, Connecticut, Maryland,Virginia, West

Virginia, Kentucky, Washington, D.C., Indiana, Michigan,

Wisconsin, Missouri, Kansas and Nebraska.

On

June 2, 2010, EPA lowered the National Ambient Air Quality

Standard (NAAQS) for sulfur dioxide (SO2).

The new standard is expected to improve public health protection,

especially for children, the elderly, and people with

asthma. In 2011, Wingra Engineering evaluated

over fifty U.S. power plants to help USEPA, state and

local air agencies identify facilities not complying with the new

air quality standard. The power plants were located in numerous

states including Maine, New Hampshire, Massachusetts,

Pennsylvania, New York, Connecticut, Maryland,Virginia, West

Virginia, Kentucky, Washington, D.C., Indiana, Michigan,

Wisconsin, Missouri, Kansas and Nebraska.

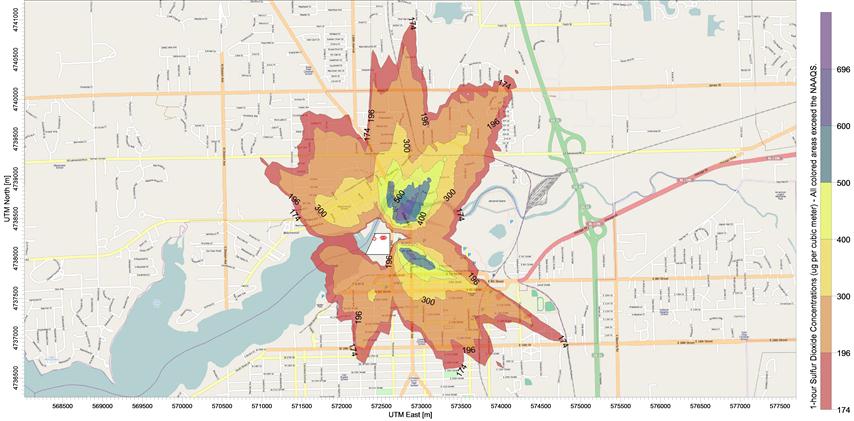

Dispersion modeling analyses were conducted following USEPA

approved procedures. Computer models included AERSURFACE to

evaluate land use, AERMAP to evaluate terrain elevations, AERMET

to process recent meteorological data, and AERMOD to predict down

wind concentrations. Operating scenarios were based on SO2

emissions approved by the

most recent air quality permit and historical actual emissions as

measured by continuous emission monitors on the boiler stacks. Air

pollution emission reductions necessary to comply with the new

standard were calculated and predicted air pollutant

concentrations were over laid onto regional and local maps to help

present

the modeling results to regulatory agencies and the general

public.

Wingra Obtains Environmental

Approvals for Wine Bottle Manufacturing Plant

in Washington

In

2010, Wingra Engineering coordinated environmental approvals to

re-open a wine bottle

manufacturing plant in Kalama, Washington. The existing

glass furnace was replaced with a new electrically-assisted,

oxygen-fired melting furnace which reduced nitrogen oxide (NOx)

emissions by 90% compared to traditional container glass

furnaces. Wingra worked with the German furnace and air

pollution control system manufacturers to assure compliance with

federal, state and local air pollution control requirements. The

project design reduced emissions below minor air pollution

source thresholds so only local permit approval by the Southwest Clean Air Agency

was required. Besides obtaining the local air quality permit,

Wingra verified the project met state environmental policy act

requirements. The plant is

expected to open during the summer

of 2012.

Wingra Helps Develop

Environmental

Management System in Wisconsin

In 2009, Wingra Engineering worked with a coated and insulated

glass manufacturer in Wisconsin to help develop their Environmental

Management

System or EMS. Each activity at the facility was reviewed to

determine raw material and energy consumption; environmental

impacts

include waste generation and pollution discharges; applicable laws

and

regulations; and, compliance with these requirements. Past

improvements

were documented and goals for future improvements were outlined.

This

summary of environmental impacts and register of legislation

became the

starting point for the company's EMS.

Wingra

Evaluates

Sites for New Manufacturing Plant in Southwest U.S.

In 2008, Wingra Engineering investigated the air pollution

control

requirements for potential sites of a new flat glass and solar

photovoltaic cell manufacturing plant in the

southwest U.S. including Arizona, New Mexico and Nevada. The

evaluation

considered the air pollution emissions from the facility;

jurisdictions

of local and state air pollution control agencies; proximity of

nonattainment areas which did not comply with air quality

standards;

and, nearby national parks and wilderness areas. Additional air

pollution control measures were developed by Wingra and then

incorporated into the project to reduce discharges and expand the

range

of acceptable plant locations.

Wingra

Obtains Air Quality Permit for Foundry Expansion in Tennessee

In 2007, Wingra Engineering obtained an air quality permit from

the Tennessee Department of Environmental Conservation for the

expansion of an iron

foundry in Etowah,

Tennessee. New electric furnaces and casting lines with a

capacity of 60 tons per hour would be constructed. Beside the

state air pollution control agency, Wingra worked with the

National Park Service and U.S. Forest Service to assure protection

of sensitive areas such as Smokey Mountains National Park. The new

equipment required approval under the Prevention

of

Significant

Deterioration or PSD major source

regulations. Wingra prepared a permit

application for the project that included an evalution of

state-of-the-art air pollution control measures and dispersion

modeling

analyses to verify compliance with air quality standards.

Wingra Obtains Air

Quality Permit for Coal-Fired Lime Kiln in Wisconsin

In 2006, Wingra Engineering successfully obtained

an

air quality permit for a new 650 ton per day coal-fired lime

kiln to be

located in

Superior,

Wisconsin. The kiln was subject to the Prevention of

Significant Deterioration air quality regulations including an

evaluation of Best Available Control Technology (BACT) and

near-field

air quality impacts. All air pollutants were controlled using

BACT or state-of-the-art air pollution control methods.

These

included the use of a fabric filter baghouse for the capture of

dust

from the kiln and materials handling operations, and use of low

sulfur

coal and a preheater type kiln to neutralize sulfur dioxide

emissions

by 92%. Combustion related air pollutants including nitrogen

oxides and

carbon monoxide were controlled by the use of a preheater lime

kiln

which reduced both energy usage and resulting stack emissions by

over

30% compared to the conventional lime kilns. The project was

designed

to assure nearby air quality impacts were insignificant for all

air

pollutants. Approval was obtained from the U.S. Forest Service

by

demonstrating that impacts on nearby Class I Air Quality Areas

including the Boundary Waters Canoe Area Wilderness and the

Rainbow

Lake Wilderness were insignificant.

Wingra Receives

Approval of First Combined Risk Analysis

Wisconsin hazardous air pollutant requirements

under

Chapter NR 445, Wis. Adm. Code, were recently changed to allow

use of a

combined risk analysis as a compliance method for carcinogenic

air

pollutants. In 2005, Wingra Engineering received the first Wisconsin Department of Natural Resources approval of a combined risk analysis for discharges

from an

iron foundry. A comprehensive emissions inventory was compiled

for 16

individual contaminants released from 82 foundry operations,

emergency

generators and natural gas combustion. To simplify the analysis,

emissions from each discharge point were reduced to an

equivalent

quantity of benzene emissions, referred to as “TEQ as Benzene”.

The

analysis verified that the estimated cumulative risk due to

foundry

operations was less than the 10 x 10-6

requirement. A technical paper on the techniques used for this

project

was presented at the national conference of the Air & Waste

Management Association in 2006. An abstract and full text of the

paper

are available on the Wingra web

site.

Wingra Successfully

Challenges Air Permit Issuance

In 2005, Wingra provided expert witness services

to

represent neighborhood residents challenging issuance of an air

quality

construction permit for melting furnaces at an aluminum die

caster and

foundry. During a five day contested case hearing, it was

demonstrated

that close proximity of residents to the foundry required more

accurate

dispersion modeling procedures. The Wisconsin Department of

Natural

Resources had failed to consider the effects of the downwash

recirculation cavity, terrain and fugitive emissions from open

doors

and windows. As a result, facility discharges violated air

quality

standards in the backyards of surrounding homes. In his

decision, the

hearing examiner amended the permit to require the foundry to

eliminate

all fugitive emissions and operate two air quality monitors in

areas

predicted to exceed air quality standards. Rather than implement

these

additional air pollution control measures, the company

subsequently had

the DNR revoke the permit.

Wingra obtains Air Quality Approvals

for

a Washington State Float Glass

Plant

near

Mount

Rainier

and

Olympic National Parks

In 2004, Wingra Engineering successfully obtained air

quality

permits for a 650 ton per day float glass plant in Washington

State.

This plant used a 200 mmbtu per hour natural gas fired

regenerative

furnace to melt sand, limestone and other raw materials to

generate a

continuous 16 foot wide ribbon of flat glass for windows and

other

glass applications. The project required approval by the local

air

quality agency, Washington Department of Ecology, and oversight

by the

U.S Environmental Protection Agency, U.S. Forest Service, and

National

Park Service. Locating a new air pollution source near national

parks

and wilderness areas increases the need for a more thorough

evaluation

of air quality impacts and available emission control methods.

The project required

issuance of a Prevention of Significant Deterioration (PSD) air

quality

permit requirements including an evaluation of Best Available

Control

Technology (BACT) and near-field air quality impacts. As BACT,

the

plant was equipped with air pollution control systems for the

control

of PM, SO2 and NOx emissions. A spray

drier -

electrostatic precipitator was used to control PM and SO2

emissions. NOx was controlled using the 3R

Process,

a combustion technique unique to regenerative furnace float

glass

plants which uses excess natural gas to create a reducing

atmosphere,

similar to the reburn process used in coal-fired boilers.

Due to complex

terrain

near the project site, a more accurate near-field modeling

analysis was

conducted using the AERMOD dispersion model and meteorological

data

collected near the site. Project impacts were below the

significant

impact levels for all air pollutants except NOx. As a

result, a regional inventory of NOx emissions sources was

developed to

model the combined impact from the project and surrounding

emission

sources, and verify compliance with air quality standards.

As Washington State

does not have a SIP-approved PSD program, USEPA Region 10

provided

additional review to verify compliance with the PSD regulations.

The project was

located

within 200 kilometers of seven Class I air quality areas

including

Mount Rainier and Olympic National Parks. A separate evaluation

was

required by the National Park Service and U.S. Forest Service to

assess

far-field impacts on air quality standards, and air quality

related

values including regional visibility and acid deposition.

Far-field

impacts were estimated using the CALPUFF model. The project was

determined to have insignificant impacts for all air quality

standards

and AQRV.

While prior float

glass

projects elsewhere in the U.S. had established BACT for the

industry

without the use of add-on control equipment, the proximity to

the Class

I areas required greater control of plant air pollution

emissions.

Additional control measures included use of a spray

drier-electrostatic

precipitator control system for glass furnace PM and SO2

emissions and a selective catalytic reduction system to control

NOx

emissions from backup emergency generator.

A technical paper on the

techniques used for this project was presented at the national

conference of the Air & Waste Management Association in

2006. An

abstract and full text of the paper are available on the Wingra

web

site.

On

June 2, 2010, EPA lowered the National Ambient Air Quality

Standard (NAAQS) for sulfur dioxide (SO2).

The new standard is expected to improve public health protection,

especially for children, the elderly, and people with

asthma. In 2011, Wingra Engineering evaluated

over fifty U.S. power plants to help USEPA, state and

local air agencies identify facilities not complying with the new

air quality standard. The power plants were located in numerous

states including Maine, New Hampshire, Massachusetts,

Pennsylvania, New York, Connecticut, Maryland,Virginia, West

Virginia, Kentucky, Washington, D.C., Indiana, Michigan,

Wisconsin, Missouri, Kansas and Nebraska.

On

June 2, 2010, EPA lowered the National Ambient Air Quality

Standard (NAAQS) for sulfur dioxide (SO2).

The new standard is expected to improve public health protection,

especially for children, the elderly, and people with

asthma. In 2011, Wingra Engineering evaluated

over fifty U.S. power plants to help USEPA, state and

local air agencies identify facilities not complying with the new

air quality standard. The power plants were located in numerous

states including Maine, New Hampshire, Massachusetts,

Pennsylvania, New York, Connecticut, Maryland,Virginia, West

Virginia, Kentucky, Washington, D.C., Indiana, Michigan,

Wisconsin, Missouri, Kansas and Nebraska.